Enterprise Asset Management Systems

EAM Systems help control, maintain and optimise the quality and performance of operational assets throughout their lifecycle. COSOL have over 23 years experience implementing leading solutions for asset management including IBM Maximo, SAP and Hitachi Ellipse.

Intelligent asset management solutions.

The amount of asset data available to organisations has exploded. The challenge for asset managers, reliability managers and operational teams is they need to be able to easily analyse, understand and act on that data to generate business value.

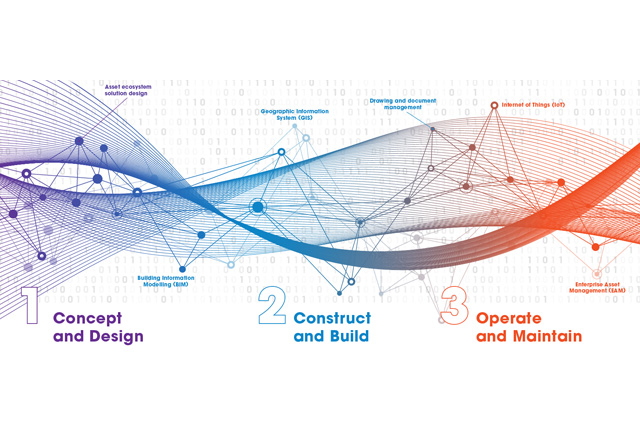

Enterprise Asset Management (EAM) systems, when leveraged as part of an integrated asset information ecosystem, address these challenges through the capture and management of asset data. They help maintain, control and optimise the quality and performance of operational assets throughout their lifecycle, increasing productive uptime and reducing operational costs.

Core capabilities of enterprise asset management systems include:

- Work Management – Centrally manage planned and unplanned work activities and capture asset data direct from the field

- Planning and Scheduling – Graphically view work schedules and dispatch crews with the skills and equipment needed for the job

- Supply Chain Management – Align the procurement of supplies and contract labour with scheduled maintenance needs

- Health and Safety – Reduce overall risk and support regulatory compliance by standardising practices and integrating them with day-to-day operations.

While many commonly used Enterprise Resource Planning (ERP) software platforms include an asset register and may offer EAM system capabilities, they are typically accounting focused and don’t prioritise operational considerations.

A dedicated EAM system, working together with tools like Geographic Information Systems (GIS), mobility, Building Information Models (BIM) or SCADA/IoT within an integrated asset information ecosystem, however, can deliver further business benefits:

- Improved asset productivity by reducing cost to run

- Improved asset operation through reduced asset downtime and better inventory optimisation.

REDUCE DOWNTIME

Time lost to equipment failure can be reduced by up to 25% when a dedicated EAM solution is implemented.

RESOLVE ISSUES BEFORE THEY HAPPEN

Collect, analyse and act on asset data to stop reacting to and start preventing equipment breakdowns.

CONSOLIDATE OPERATIONAL APPLICATIONS

A single technology system to manage virtually all asset types. Processes are unified and standardised for wide-ranging functions.

CENTRALISE ASSET INFORMATION

An EAM system tells maintenance managers where an asset is, what it needs, who should work on it and when to automate critical workflows.

EAM SYSTEMS AND THE ASSET INFORMATION ECOSYSTEM

Learn more about integrating Enterprise Asset Management systems into the asset information ecosystem.