Advanced Maintenance Solutions

Achieve predictive and preventative maintenance through advanced maintenance solutions that fuse IoT, AI and machine learning technologies to capture, integrate, visualise and analyse asset performance data for improved reliability.

Enable advanced maintenance solutions that find the balance between reducing risk and optimising assets.

Asset Performance Management (APM) systems fuse IoT, AI and machine learning technologies to capture, integrate, visualise and analyse performance data to improve the reliability and availability of physical assets. APM includes the concepts of condition monitoring, predictive forecasting and reliability-centred maintenance (RCM).

Building on EAM as the system of record, APM tools and technologies are designed to help engineers, planners and maintenance leaders make better decisions on which maintenance and inspection activities to perform and when. Organisations invest in APM to reduce unplanned (and unnecessary planned) repair work, improve asset availability and safety, minimise maintenance costs and reduce the risk of failure of critical assets by:

- monitoring performance metrics in real-time through connected sensors

- automating condition-based preventive measures

- identifying causes of recurring issues

- analysing data to anticipate and minimise, if not completely eliminate, asset failures that lead to unscheduled downtime, overtime, unplanned acquisition of parts and deferral of scheduled maintenance activities.

REDUCE FREQUENCY OF ASSET FAILURES

Monitor asset conditions with registered IoT devices that send sensor data to predict failure and trigger automated actions to avoid breakdowns.

OPTIMISE PREVENTATIVE MAINTENANCE

Combine asset records and sensor data to take action based on insight into asset health instead of doing unnecessary preventive maintenance.

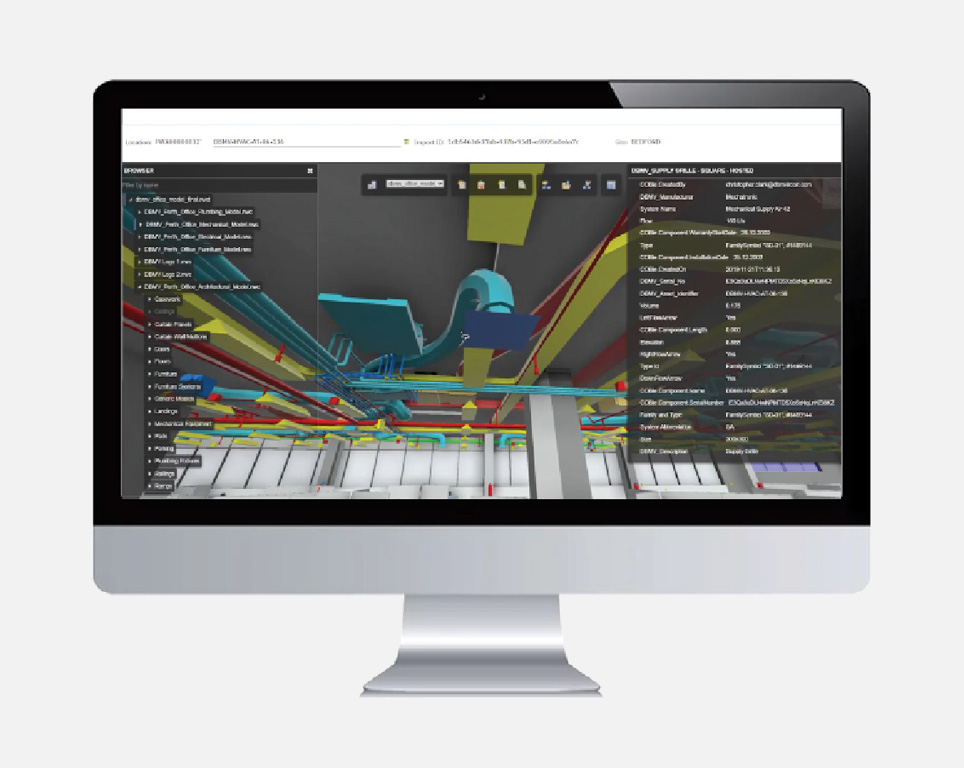

ENTERPRISE-LEVEL DATA VISABILITY

Integrate data from multiple sources to gain insights about operating states across the organisation in a single dashboard.

INCREASE ASSET AVAILABILITY

Keep track of conditions, costs, performance and remaining useful life to reduce asset failures and minimise downtime.

REDUCE OPERATIONAL RISK

A deeper view of asset status helps you focus on the right assets.

REDUCE CAPITAL REPLACEMENT DECISION TIME

Make replacement planning more accurate and efficient with powerful analytics that provide a clear view of your assets.