At a glance

- Operational Readiness Backlog Elimination: COSOL cleared a 12-month backlog, stabilising the miner’s asset portfolio.

- SAP Master Data Improvement: Resolved gaps in SAP configuration and maintenance data for better execution and budgeting.

- Optimised Processes: Documented and embedded new operational readiness processes into daily workflows for long-term value.

- Sustainable Outcomes: Reduced risk, eliminated costly reactive maintenance, and refocused efforts on preventative strategies.

For a leading Australian coal miner

Every asset in the mining industry requires a considered approach to operational readiness. Ensuring performance from day one to disposal requires a structured, thorough and competent integration of documentation, personnel, processes and systems.

Because of its specialist nature, in-house teams often struggle to complete operational readiness effectively for diverse asset portfolios.

Labour hire solutions can sometimes help close capacity gaps in the master data space. However, their capability, sense of ownership and approach to project management varies - which increases costs to the business.

Challenge

One of Australia's top coal miners* found itself in this difficult situation. The company's engineering team was struggling to support a wide range of unique critical assets - resulting in a chain reaction that led to:

Their inconsistently configured SAP enterprise resource planning system was also not aligned with the company's requirements or team needs.

COSOL set out to overhaul the miner's operational readiness process and reduce their backlog over a 12-month project.

Improving asset performance in this situation required

01

Gaining a clear understanding of the issues and their root causes.

02

aligned decisions on the best solutions - considering the unqiue business context

03

coordinated actions to deliver results quickly

Solution

02 Decide

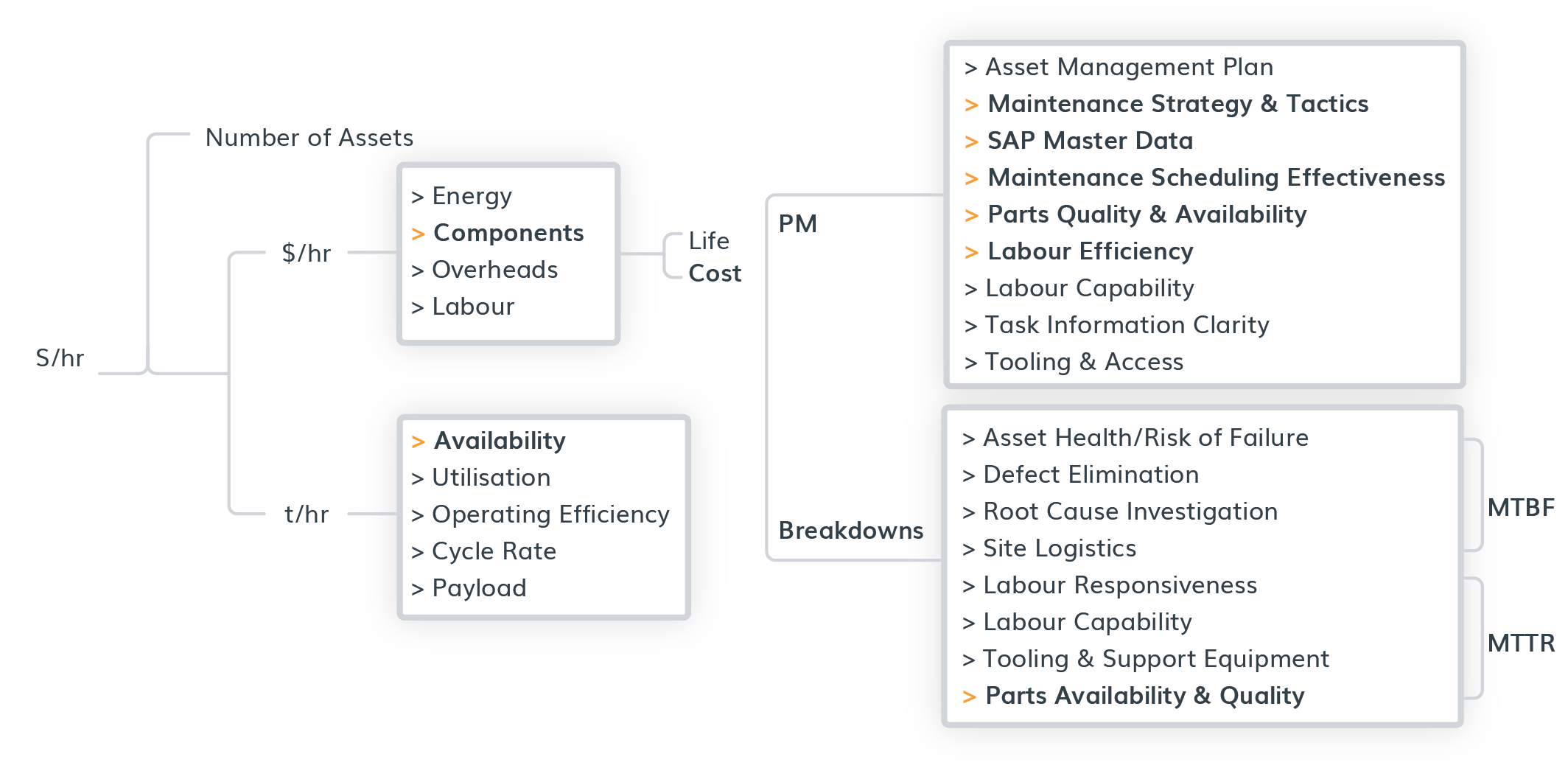

From its initial review, COSOL identified two broad areas of improvement - breaking those areas down into target business value levers:

- Operational readiness process - to improve consistency of results

- SAP master data backlog reduction - to support maintenance execution and budgeting

COSOL began by...

taking the time to understand the issues that regularly arise in the client's asset portfolio. Then, the team began identifying solutions for the underlying problems to prevent new ones from occurring.

03 Act

Operational

COSOL made sure that the proposed solutions could easily and practically integrate into the company's processes and workflows.

This involved:

- Defining and optimising the operational readiness processes

- Documenting, validating and work-flowing the new processes - ensuring stakeholders understood their roles and that there were no gaps.

- Integrated process documentation into the company's day-to-day operations - to lock in improvements beyond the project's timeline and key personnel.

SAP master data backlog reduction

Executing substanial 'heavy lifting' operational readiness activities, COSOL eliminated the asset backlog and brought the process back under control.

This involved:

- Portfolio prioritisation

- Operational readiness planning for each asset

- SAP updates, including:

- Functional location (FLOC) updates

- Maintenance plan changes

- Task Lists

- Materials and bill of materials (BOM) setup

- Testing and validation

- Internal stakeholder relationship repair - including work quality verification and sign-off

Outcome

A year later - thanks to COSOL's support - the client is in a far more stable position. With a fit-for-purpose process in place, executing operational readiness is part of their day-to-day business activities.

Fully

cleared backlog

of assets requiring critical maintenance

Updated and

reconfigured SAP

with gaps in master data resolved

Empowered the client to

refocus on preventative maintenance

spending less on repairs