This article is an excerpt from our insights eBook - 'The Path to Mining Productivity'. The insights draw on 23+ years mining industry expertise in combination with our technical and functional knowledge of asset management.

In this excerpt

- We discuss the importance of putting asset data at the centre of mining operations to provide accurate insights for decision making

- We introduce the integrated asset information ecosystem for mining and how it integrates with existing platforms such as an ERP

- We summarise how mining organisations can achieve digital asset management maturity that leverages latest technologies and the abundant amount of asset data already available to them.

Mining organisations can unlock the tremendous potential of their assets when they understand everything about their performance and how to extract maximum value from them.

Mining companies are currently experiencing an ‘explosion’ in the amount of asset data they have at their disposal. But their ability to extract valuable data insights that can deliver game-changing asset productivity gains can often be severely constrained by siloed technical architecture and outdated processes.

The mining sector in particular can learn a great deal from asset-intensive organisations in other sectors that are extracting maximum value from their asset data. These innovative organisations understand that integrating data sources and capturing asset performance insights can not only yield productivity benefits and ensure profitability but can also help them achieve ESG goals and secure future growth.

What these effective organisations have in common is a tried-and-tested asset management solution that puts data at the centre of their organisation’s operations.

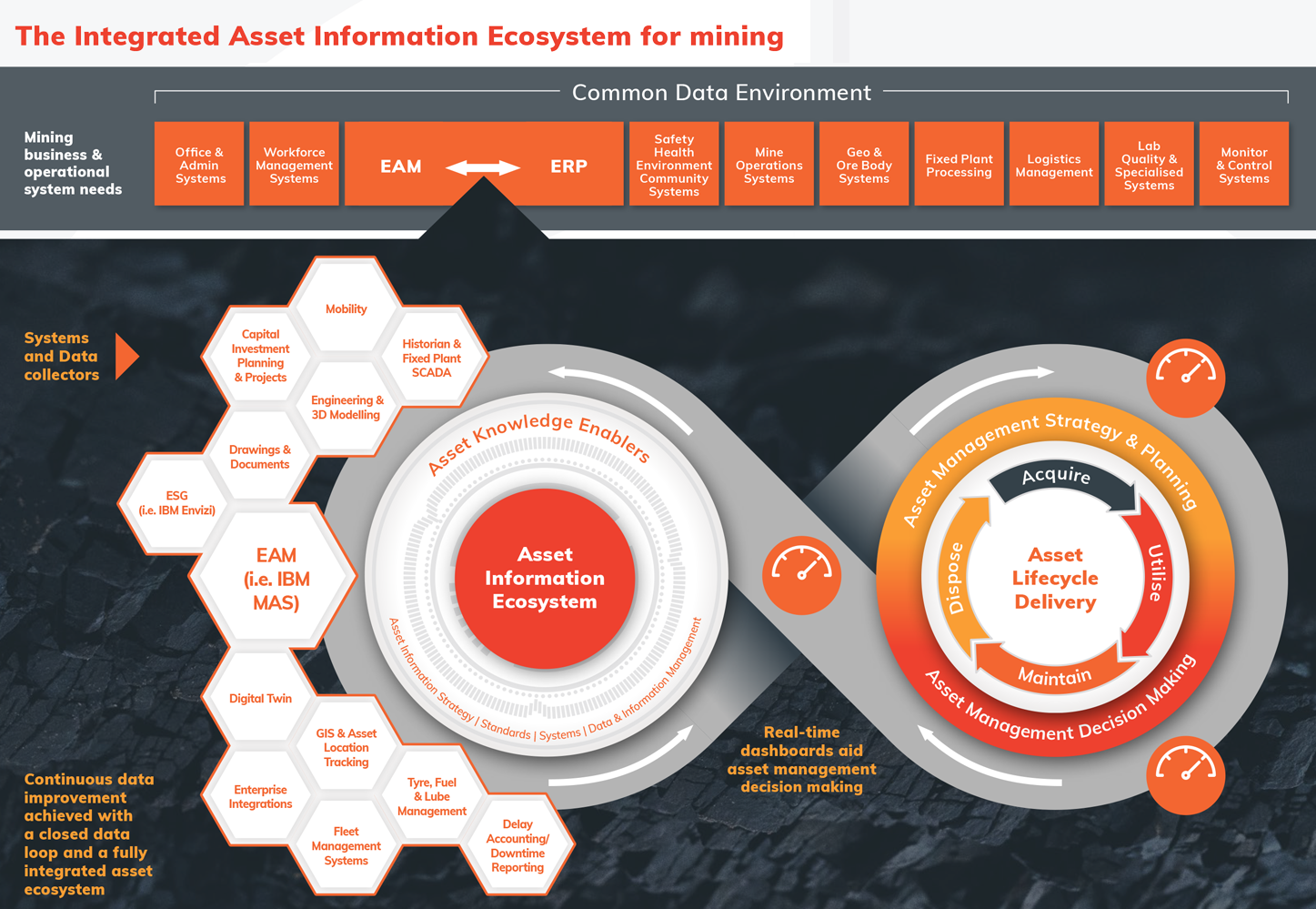

Why a Common Data Environment is essential

When an organisation establishes a Common Data Environment (CDE), they can capture data insights from a ‘single source of truth’ that asset and reliability managers and members of other departments can rely on to analyse, interpret and act upon. A CDE essentially creates a common language between integrated systems and enables information to flow freely and easily between them.

When an organisation’s Enterprise Asset Management (EAM) platform such as IBM Maximo is underpinned by a CDE, the right data is delivered to the right decision maker at the right time. Establishing a CDE is the essential foundation that allows organisations to optimise the performance of their assets.

With data made central to an organisation’s asset management operations, it becomes possible for that organisation to achieve Digital Asset Management Maturity. Reaching this state means an organisation has transitioned from a scheduled or reactive maintenance model to the optimal predictive maintenance model.

How an integrated Asset Information Ecosystem can bolster productivity

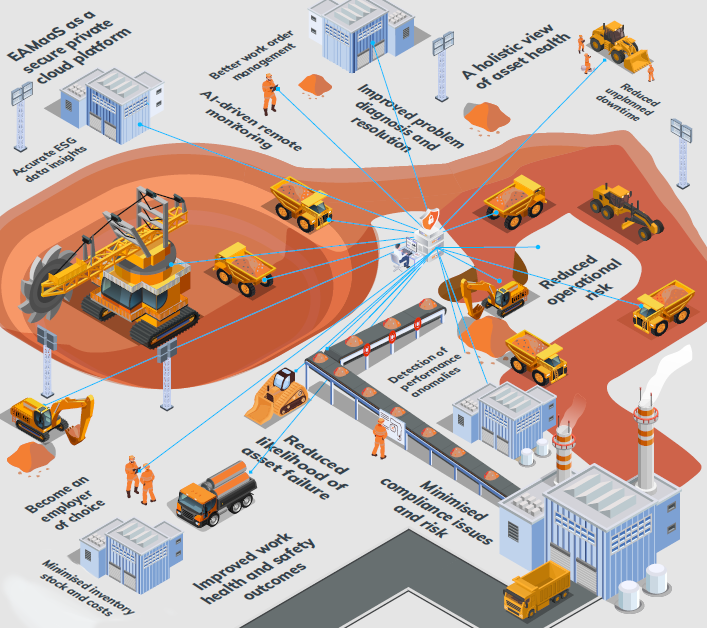

The good news is that mining organisations (as with those in other sectors) can implement an EAM platform that integrates with their existing Enterprise Resource Planning (ERP) platform to enable them to achieve a predictive maintenance model. This EAM platform becomes part of their integrated Asset Information Ecosystem and is also supported by real-time, data-driven insights that equip asset decision-makers to minimise unplanned asset downtime, optimise asset productivity, work towards ‘Zero D’ and almost completely eliminate asset failures.

The ecosystem approach to EAM enables organisations to make better asset lifecycle decisions and streamline efficiencies in inspections, maintenance, repairs and improvements. The productivity gains they derive from reduced maintenance costs and reduced lost time to equipment failure can significantly boost their competitiveness and maximise their profitability.

Towards greater asset intelligence

COSOL has extensive experience assisting asset-intensive organisations to reach their asset performance potential. For over 20 years COSOL has worked closely with asset-intensive organisations in the mining sector to help them realise their strategic objectives by bringing together their technologies, data, people and processes. Through the combined expertise of the COSOL group, we are able to assist optimise our customers Asset Information Ecosystem and accelerate the organisational changes to help them achieve faster ‘time-to-value’.

The first step is to establish where an organisation is on their path to Digital Asset Management Maturity and what technologies, processes and strategies they need as part of their Asset Information Ecosystem. Drawing on our group's expertise and industry knowledge, we help build a Roadmap consisting of sequential stages, each of which delivers productivity benefits, establishes new asset information capabilities and sets new business standards once each milestone is reached. By the time an organisation attains Digital Asset Management Maturity, their data and systems are integrated and improve continuously over time.

Positioning mining organisations for growth

Exciting advances in data capture, advanced analytics, Machine Learning, Artificial Intelligence (AI) and the Internet of Things (IoT) mean asset and reliability managers can now make smarter and fact-based decisions about their organisation’s assets. The result is that mine operators can maximise the useful life of their assets, reduce asset downtime, minimise inventory stores and unlock productivity gains.

As the leaders of forward-thinking mining organisation understand, reaching a state of digital asset management maturity doesn’t just offer a technology opportunity, it offers a compelling business opportunity.