At a glance

- 37% increase in Liebherr 996 fleet production within 12 months.

- Shifted site focus from costly breakdown repairs to preventative maintenance.

- Simplified fleet strategy reduced complexity and improved productivity.

- Close collaboration between COSOL and site leadership ensured sustainable improvements.

For a large South African iron ore mine

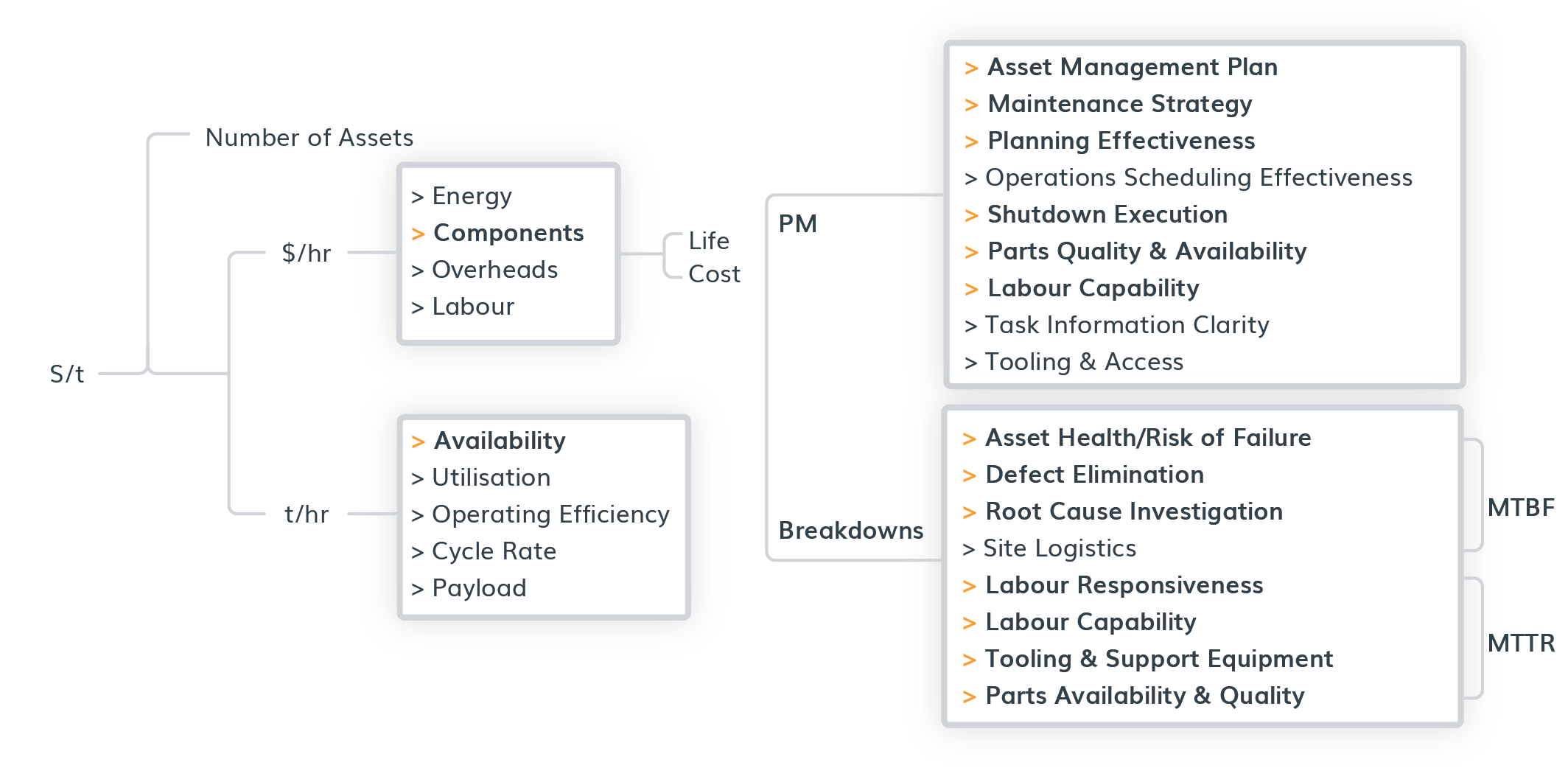

Poor performance of heavy mobile mining equipment limits site production volumes, and subsequently business revenue.

The causes of poor asset performance are often complex. Seperate but typically interdependent issues create a vicious cycle that sites struggle to turn around.

01

Breakdowns consume available resources over preventative maintenance.

02

Leadership focus shifts to stopping availability loss and breakdowns.

03

Cost rise and leaders face pressure to reduce costs

04

Decision to push out preventative maintenance to meet availability targets.

Improving asset performance requires:

01

deep and genuine understanding of these issues and their root causes,

02

aligned decisions regarding the best solutions, considering the unique business context, and

03

coordinated actions to deliver results quickly

Challenge

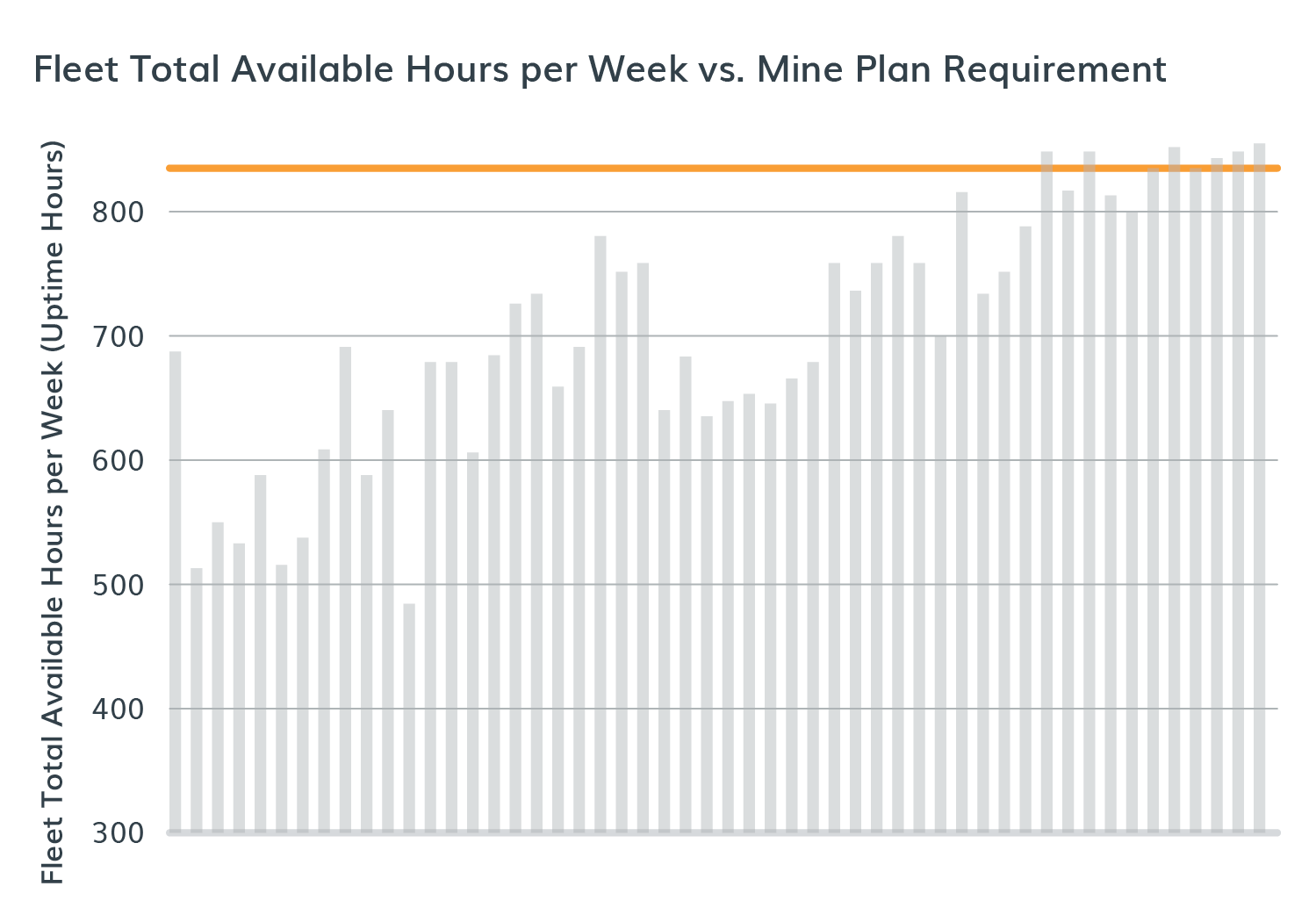

Fleet performance issues were constraining site production at a well-known iron ore mine in South Africa*. Site leaders found themselves under significant pressure to come up with solutions and deliver quickly.

Busy managing their underperforming mining operation, the client’s team didn’t have the time, resources or know-how to turn this issue around.

*Anonymised to protect the client’s business.

Solution

01 Understand

Determine the problems and their root causes

COSOL’s data analytics team began by taking a performance baseline - including data a validation and in-field performance loss statement - to determine current vs. potential performance.

The team...

- identified areas of improvement.

- evaluated the impact of each area on asset availability and site productivity, and

- developed a prioritised list of improvement opportunities by business value.

02 Decide

Find the solutions that fit best

The client’s problems were complex, necessitating a multi-faceted solutions. Collaborating with the site leadership team, COSOL developed an improvement program, with detailed plans for each major work stream.

The group reviewed any concerns and ‘pet projects’ against baseline data and conducted sensitivity analyses. Further live testing of project impact sensitivity on the overall business value case helped align the team on what mattered most.

Solutions considered the site’s unique context, including:

- Asset condition

- Maintenance strategy

- Operating conditions

- Mine plan asset allocation

- Supply chain constraints

- Labour laws

- Community requirements

- Maintenance labour capability

- Budget constraints

03 Act

Implement changes

Over a period of 12 months, the COSOL team closely supported the site-led performance turnaround program and performed three key roles.

- Provide governance and assurance for business executives

- Coach site leaders

- Offer additional project team capacity to support front-line personnel

Noteworthy actions included:

- Develop a holistic fleet strategy for the site HME, simplifying the fleet to reduce complexity for the maintenance team.

- Park-up of two under utilised 800-tonne excavators

- Modification to mine plan machine allocation pathways to improve stockpile loading rates and reduce excavator trimming time and cost

- Evaluation of contract options to reduce the strain on existing maintenance resources

- Roll out a targeted shovel and excavator reliability improvement program

- Maintenance strategy and tactics review and refinement

- Shutdown optimisation, standard planning template and execution structure.

- Component age and health baseline

- Risk management framework to reduce component failure risks and breakdown failure cost.

- Planning priority and process refinement, and reduction in high priority component backlog

- Component vendor selection and rebuild quality.

- Provide training, processes, systems, and support for the team to sustain improvements long-term.

Outcome

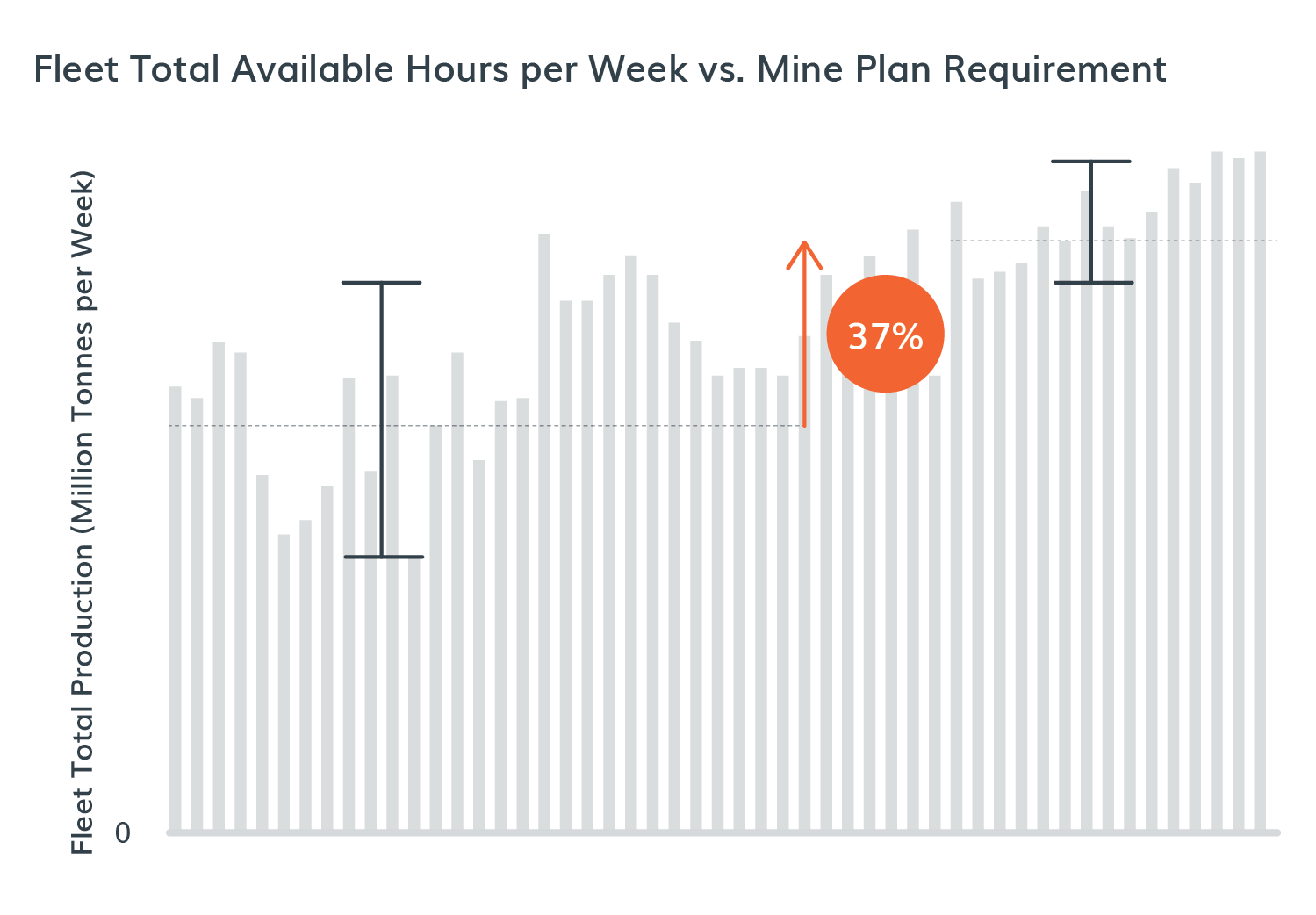

Within 12 months, COSOL was able to turn around performance of critical assets that directly constrained the mine’s productivity. Because of this, the client saw significant improvements in both fleet uptime and mine production.

Empowered to

shift focus

from breakdown repair towards preventative maintenance and component.

37% increase

in Liebherr 996 fleet production (8.5 to 11.6 metric tonnes per annum per asset)

Stronger

company-wide production

and revenue

results