At a glance:

- Optimised inventory management applies a rules-based engine to analyse inventory variables such as criticality, lead time, price and usage.

- Using an inventory optimisation platform specifically built for MRO environments, enables organisations to minimise their greenhouse gas emissions by reducing waste and energy consumption associated with procuring, storing and handling inventory.

- With sustainable inventory management strategies in place, organisations can improve their ESG performance, enhance their reputations and inject resilience and responsibility into their supply chains.

- An Inventory Optimisation Opportunity Assessment can identify the value and opportunity available to asset-intensive organisations benchmarked against their industry.

Reduce your organisation’s carbon footprint when you optimise MRO inventory into your operations.

In today’s competitive business environment, debating whether to incorporate sustainability into your operations is no longer an option. Embedding a values-based approach into your business strategies is essential to meet evolving investor expectations, satisfy consumer demand and abide by regulatory requirements. It can also give your organisation the competitive advantage it needs.

Incorporating sustainable practices into your organisation’s inventory management is one way to significantly reduce waste and energy consumption, and minimise greenhouse gas emissions. By optimising stock levels and improving the efficiency of the resources needed to run your operations, your organisation can demonstrate its commitment to environmental stewardship while optimising your operations and asset performance.

If reducing waste and energy consumption to minimise greenhouse gas emissions was not reason enough, adopting a sustainable approach to inventory management and supply chains has been shown to make good business sense:

![]()

A study by Accenture found that the average operating margins for companies with high ESG performance ratings are 3.7 times higher than those of lower ESG performers.1

The sustainability benefits of an optimised inventory management system

With organisations increasingly aware of their ESG responsibilities, sustainable inventory management has become as essential mechanism for reducing greenhouse gas emissions across the value chain. By implementing sustainable inventory management strategies, organisations can not only take a large step in their decarbonisation journeys, they can enhance their reputations and inject resilience and responsibility into their supply chains.

Research by McKinsey shows that organisations that implement a strategic inventory management approach and optimise their supply chains can substantively reduce their carbon emissions while also achieving operational efficiencies and cost savings.2

Introducing efficient logistics processes can reduce Scope 3 emissions, which are often the largest component of an organisation’s carbon footprint. Optimising transportation routes, and using telematics and advanced analytics to improve vehicle utilisation can cut costs and reduce carbon emissions. Using advanced analytics to monitor and optimise inventory, and applying a rules-based engine to analyse variables including criticality, lead time, price and usage, delivers data-driven insights that can enable decisions that further reduce waste and emissions.

The shift towards sustainable inventory management is one that all forward-thinking businesses need to commit to. Not only is it expected of environmentally conscious consumers, it’s a strategic decision that demonstrates an organisation’s commitment to ESG in action. For asset intensive organisations, implementing a sustainable approach to MRO inventory management in particular can lead to:

- Reduced waste: Sustainable MRO inventory management reduces waste and energy consumption by optimising stock levels, reducing logistic and transportation, and improving resource efficiency.

- Cost efficiency: Reducing waste contributes to cost savings, and optimised stock levels reduces overstocking and the resources needed to hold this excess stock.

- Brand reputation: Organisations that embed sustainable practices into their inventory management are regarded as effective environmental stewards and attract environmentally conscious customers.

- Risk management: Working with suppliers who have demonstrated their commitment to sustainability strengthens the entire supply chain. Relationships such as these foster innovation, create a supply chain that is adaptable to market fluctuations, and enable resilience in the face of regulatory landscape changes.

- Business future-proofing: Sustainable MRO inventory management can buffer organisations against evolving environmental regulations, supply chain constraints and consumer demands, positioning them for long-term success.

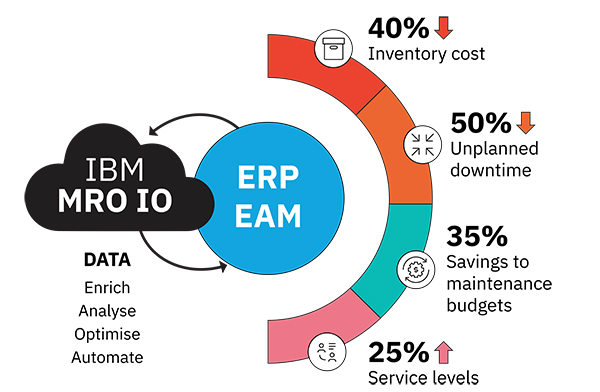

Finding balance with your inventory

MRO inventory optimisation is fundamentally about balance. If your organisation maintains an excess of tools, spare parts and consumables, the cost to procure, store and handle that inventory can become crippling. There is also the risk that parts become obsolete the longer they remain in warehouse storage, meaning they can’t be used or have a reduced lifespan if they are. Hold too little and your organisation runs the risk of unplanned downtime caused by critical inventory shortages that prevent routine maintenance and emergency repairs from being completed.

Either way, underlying MRO inventory management issues can have an adverse effect on the performance of your assets, how your organisation meets service levels, and how it manages costs.

IBM’s MRO Inventory Optimization (IBM MRO IO) solution is a cloud-based inventory management platform that combines advanced algorithms and prescriptive analytics to improve forecasting accuracy, identify criticality and minimise unplanned downtime. IBM MRO IO integrated with an organisations ERP and/or EAM enables maintenance, procurement, inventory and supply chain groups to work better together to ensure that MRO inventory items are maximised while balancing cost and risk.

When inventory levels are ‘right-sized’ organisations can make informed decisions about managing their assets while increasing service levels, minimising unplanned downtime due to parts, and freeing up working capital to allocate to other strategic priorities.

Optimised MRO inventory levels can also significantly boost your organisations’ sustainability performance. With an accurate and detailed view of MRO inventory and recommendations for optimising inventory and reorder levels for each stock item, dead inventory can be eliminated and the need for emergency shipments significantly reduced. With just the right amount of MRO inventory at your organisation’s disposal, you can also devote an optimal amount of warehouse space to storing it, cutting down on energy consumption and the need for complicated logistics management.

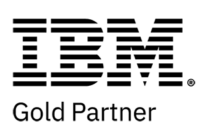

Above: IBM MRO IO integrates with EAP's such as SAP, Oracle and Pronto as well as EAM's such as IBM Maximo

Why optimising MRO inventory is so challenging

Eliminating excess inventory and inefficiency is a challenge for most modern organisations. Many asset-intensive organisations operate in the dark, faced with managing a multitude of stock items in different locations and with varying shelf lives. Attempts to tackle inventory optimisation using outdated methods often result in failure, with manual spreadsheets, internal experts and customised applications frequently unable to handle the complexities inherent in managing modern inventories.

Finding the exact balance between under- and over-stocking is elusive, with excessive inventory driving higher costs for procurement, holding and handling, increasing obsolescence risk, and too little inventory creating stockouts of critical spare parts, leading to unplanned downtime. This graphic shows how optimal stock levels create a balance, represented by the gold star:

Above: The cost of under or over stocking

Fortunately, by using a powerful analytical tool such as IBM MRO IO, inventory managers can overcome the visibility and data sharing challenges they face and gain an accurate and real-time view of their organisation’s supply chain and stock levels.

IBM MRO IO provides operational control and accurate data around the process of ordering, storing and moving the items and equipment needed to operate and maintain assets and facilities. Optimisation takes this to the next level by capturing, analysing and applying data-driven insights to inventory management processes.

Improving management of MRO spares and consumables inventories creates benefits that massively outweigh the disadvantages of implementing a best of breed inventory optimisation technology. By using a modern tool, automating processes and embedding inventory management best practices to optimise MRO, asset-intensive organisations can achieve significant results.3

- Up to 50% reduction in unplanned downtime related to parts

- Up to 40% reduction in inventory costs

- Up to 35% savings in maintenance budgets

- Up to 25% increase in service levels

Optimise your MRO inventory with COSOL

Meeting sustainability goals requires an accurate, real-time view of stock levels, warehousing operations and supply chain logistics. Using IBM’s cloud-based MRO IO optimisation platform, which has been specifically designed to overcome challenges associated with asset-intensive environments, organisations have a golden opportunity to embed sustainable practices into their inventory management and supply chains.

By optimising their inventory management processes, organisations can reduce waste and inventory costs, minimise unplanned downtime, and deliver tangible, sustainable results over time.

![]()

With IBM Maximo MRO Inventory Optimization, a major utility achieved net improvement in MRO inventory costs of $25 million and brought their 10% inventory growth rate down to zero.4

Get started with an Inventory Optimisation Opportunity Assessment from COSOL

COSOL can get your organisation started on your journey to optimised MRO inventory. Our Opportunity Assessment will determine what value can be gained from optimisation of your MRO inventory and what process, technologies and solutions are needed to maximise the benefits.