At a glance

- AI helps reduce maintenance costs without compromising asset reliability

- Data-driven insights improve timing and prioritisation of maintenance tasks

- Smarter planning leads to fewer breakdowns and better use of resources

- Small, informed decisions today prevent costly problems tomorrow

Article by Craig Lefoe,

CEO of Toustone | COSOL

Maintenance is essential to keeping infrastructure running, but it’s also one of the hardest areas to manage, especially when budgets are tight.

Organisations are asking the same question: how do we reduce maintenance costs without compromising the performance or reliability of our assets?

Artificial intelligence is helping teams find that balance. Not by overhauling systems, but by making better use of the data they already have to support more informed decisions.

Maintenance decisions are hard to get right

Most maintenance teams operate between two extremes. On one side, scheduled maintenance happens whether it’s needed or not. On the other hand, issues are left until they break. Both approaches have hidden costs.

When servicing is done too early, resources are used unnecessarily. When it’s done too late, the cost of repairs and the disruption to services is much greater. For teams managing ageing infrastructure, labour shortages, and rising costs, getting this balance right is more important than ever.

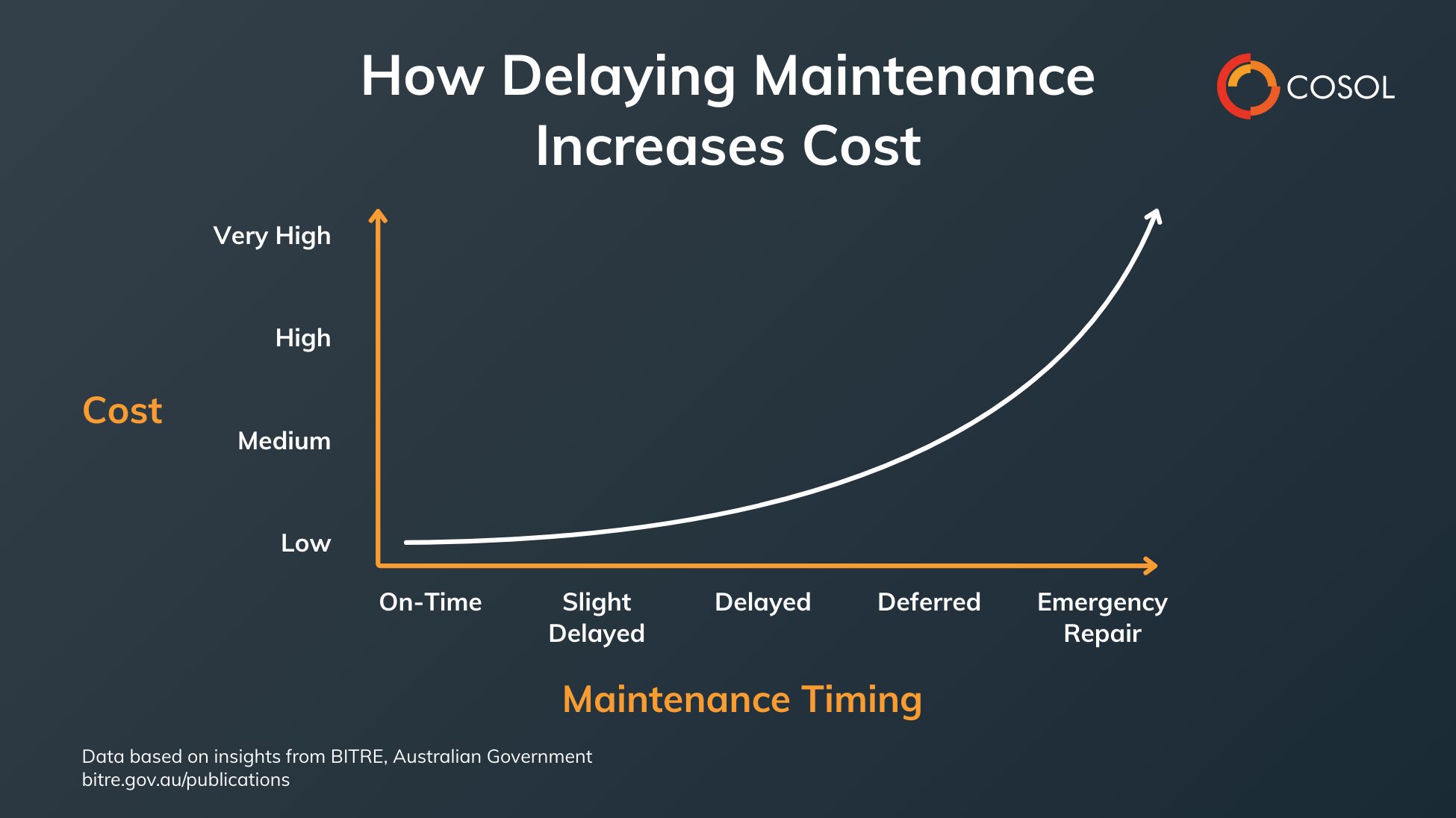

The Bureau of Infrastructure and Transport Research Economics (BITRE) notes that deferring maintenance increases costs across the entire network. Roads in poor condition, for example, lead to higher expenses for both asset owners and users. Timely, proactive treatment helps avoid this escalation and keeps long-term costs lower.

Think of it like a slow leak in a pipe. You can patch it early, or wait until it bursts and floods the system. One costs a few minutes. The other costs your weekend and thousands of dollars.

AI brings visibility and better timing

AI helps teams identify issues earlier and act before failure occurs. By analysing asset usage, past faults, and environmental factors, AI models can recommend when to take action and when it’s safe to wait.

The result is a clearer picture of what needs attention now, and what can wait. It’s not about doing more, it’s about doing what matters most.

This approach enables:

-

Less unnecessary maintenance

-

Fewer breakdowns and disruptions

-

Better use of skilled labour

-

Smarter ordering of parts and materials

Making the most of limited resources

Skills shortages and rising labour costs mean teams need to do more with fewer people. AI supports better workforce planning by identifying which jobs are urgent and which ones can wait. That means field teams can focus their time where it matters most.

It also helps with inventory control. Instead of stockpiling parts “just in case”, organisations can forecast actual needs and order accordingly.

This kind of forward planning not only saves money but also reduces stress on staff trying to respond to unexpected breakdowns or delays.

As Craig Lefoe, CEO of Toustone | COSOL, explains:

In a tightening market, making confident, data-driven decisions is key. AI gives our clients the clarity they need to balance cost and reliability without sacrificing either.

Small changes add up

This isn’t about replacing systems or rewriting processes. It’s about improving the decisions that already happen every day and using data to support them.

At Toustone | COSOL, we help clients turn complex datasets into something useful. From maintenance planning to forecasting and budgeting, we work alongside businesses to design solutions that are practical, clear and built for the long term.

Because in a time where every dollar matters, better decisions begin with better visibility.

About Craig Lefoe

COSOL are IBM Gold Partners and IBM Maximo specialists with over 15 years experience helping asset intensive organisations implement and upgrade their EAM systems as part of their asset information ecosystem.