At a glance

- Predictive monitoring with ML detects early asset faults, reducing downtime and costs.

- Real-world use cases span manufacturing, utilities, and renewables - delivering proven impact.

- ML tools like Amazon Rekognition enable faster, safer, and smarter inspections.

- A structured adoption roadmap helps embed ML into maintenance workflows at scale.

While much of the spotlight today is on agentic AI and its futuristic potential, it’s easy to overlook the fact that many organisations already have access to powerful, mature machine learning tools that can drive immediate value - especially in asset maintenance.

Machine Learning (ML) is rapidly transforming asset management and, more specifically, asset maintenance across industries such as transportation, mining, utilities, and manufacturing. From improving inspection accuracy to predictive monitoring capable of preventing failures before they occur, ML is delivering tangible results that improve operational reliability and reduce costs.

In this article, I’ll explore how proven ML applications are already being used in real-world scenarios - and how asset-centric organisations can apply these lessons to optimise maintenance strategies.

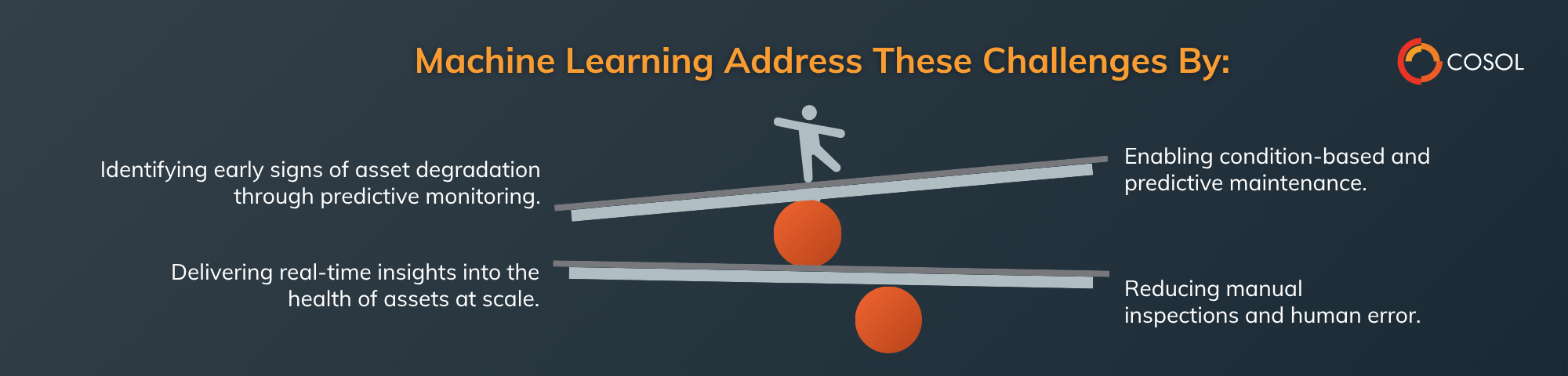

Why Machine Learning Matters for Asset Maintenance

Asset managers face increasing pressure to ensure reliability, minimise downtime, and extend asset life. Traditional maintenance methods - manual inspections, reactive fixes, and time-based servicing - are often inefficient and costly.

Impact of Real-World ML Applications with Asset Maintenance

Asset-centric industries can take their cues from several impressive real-world ML use cases, including:

How to Apply ML in Your Asset Maintenance Strategy

To successfully embed machine learning into your maintenance strategy, it’s important to follow a structured, phased approach that ensures both technical feasibility and operational impact.

Step 1: Identify Maintenance Pain Points

Start with areas that are cost-intensive, require frequent inspection, or have a history of unplanned downtime. Examples include visual inspections, high-failure-rate components, or dispersed assets.

Step 2: Evaluate Data Availability And Quality

Successful ML depends on having quality data. Review what’s available - sensor logs, inspection photos, work orders - and determine whether it's structured, labelled, and complete.

Step 3: Work With A Specialist Partner

Engage a partner with deep expertise in both asset management and machine learning implementation. The right partner can help identify high-impact use cases, accelerate deployment, and ensure alignment with industry-specific requirements. I'd confidently say, the right partner is us.

Step 4: Run A Pilot Using Off-The-Shelf ML tools

Platforms like Amazon Lookout for Vision, Rekognition Custom Labels and IBM Maximo Application Suite (MAS) as part of their Visual Inspection Modules, Predict or Assist Modules, are user-friendly starting points. They enable you to train and deploy ML models without needing an in-house data science team.

Step 5: Embed ML into Maintenance Workflows

Ensure that insights generated by ML are integrated into your maintenance planning systems and field operations. This enables timely, data-driven decision-making.

Step 6: Scale Across Site and Asset Classes

Start with areas that are cost-intensive, require frequent inspection, or have a history of unplanned downtime. Examples include visual inspections, high-failure-rate components, or dispersed assets.

Looking Ahead: ML as a Core Maintenance Capability

Machine Learning is no longer experimental - it is driving measurable improvements in asset maintenance across industries. Whether you're managing rolling stock, conveyor belts, substations, or heavy equipment, ML-enabled predictive monitoring of assets can help reduce failure risk, streamline inspections, and maximise asset life.

By applying proven ML applications and taking a structured approach to implementation, asset-centric organisations can modernise their maintenance strategies and gain a powerful edge in operational performance.

About Adam Sharp

Adam Sharp has spearheaded the delivery of Decision Intelligence solutions across the Asia Pacific for decades. Adam has an extensive background in using data to optimise operations in asset-intensive verticals, like transportation, natural resources and logistics.

As an avid cyclist, Adam understands the nature of endurance and perseverance. This is not only reflected in his personal life but also in his approach to applying statistical and data analysis techniques in practical business scenarios to enhance decision-making.