At a glance

- The key to a successful asset ecosystem is to have clear processes and ownership rules for the data flowing between systems.

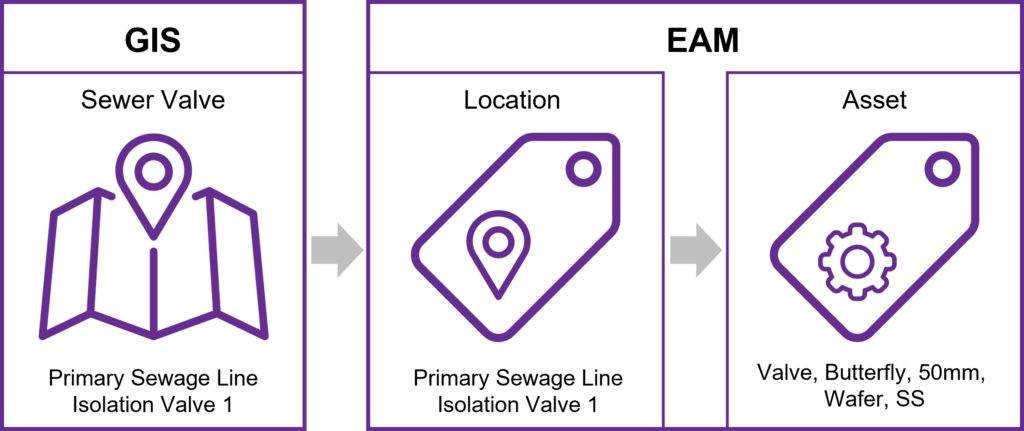

- Asset data should remain the responsibility of the EAM and inherit location data from the GIS.

- As assets move through their lifecycle, the best tools to capture and manage asset data will change.

- Read Part 1 of this integration series here: The three essential steps to successfully integrating GIS in asset management.

Enterprise Asset Management (EAM) works best when information flows freely between the numerous systems used to manage the asset lifecycle. We call this collaborative and dynamic environment the Asset Information Ecosystem.

Each enterprise system will have its strengths and there are unlikely to be clear lines of demarcation between them - many systems will need a unique identifier to record an asset and there are many different ways of looking at location (a customer's address, the coordinates of a fire hydrant, or location of a part within an assembly). This is why clear processes and ownership rules for the data flowing between systems is critical to success. Without it, the risk of data corruption, or data loss, is magnified. Establishing these business rules is complicated by the fact that data, the ways in which it is used and the applications in which it is maintained may change over the course of the asset lifecycle.

When integrating the Asset Information Ecosystem, we must start by understanding the relationship between the two most common components - assets and locations - then explore how creation, access and maintenance of this data changes over the course of an asset's life.

Asset or Location?

Assets are usually itemised and controlled through an Enterprise Asset Management system (EAM), while locations are typically recorded and managed in a Geographic Information System (GIS) for mapping and spatial analysis purposes. Your understanding of what constitutes assets and locations will likely be shaped by your perspective and involvement in the asset management function.

What is an asset?

ISO 55001 Asset management – Management systems – Requirements defines an Asset as anything that can - or has potential - to realise value for an organisation. This includes both physical assets and intangibles such as intellectual property, software or even a brand.

Business rules around what constitutes an asset typically take a financial viewpoint which sees essentially anything with value as an asset of some description. While this approach generally works for finance systems, a maintenance-focused asset management system need not track all asset types that have limited or no asset maintenance requirements (e.g. intangibles, land, non-field IT hardware). The finance view of assets takes on a more rolled up view and is less concerned about components, whereas the maintenance view is interested in the component detail and performance. The compromise is to allow for dual views, one rolled up and the other detailed. Again this additional level of separation can cause inconsistencies when trying to reconcile.

Most asset-intensive organisations will already have an Asset Management Policy that will demarcate the different asset categories and how they are managed, e.g. physical infrastructure vs financial assets. This policy needs to ensure the purpose for which data is required to ensure that relevant information flows through the Asset Information Ecosystem.

An example set of business rules defining an asset for the purpose of the asset information ecosystem could look something like:

|

BUSINESS ASSET RULES |

MAINTENANCE ASSET RULES |

|---|---|

|

Lifespan of more than one year |

Lifespan of more than one year |

|

Purchase price of more than $1,000 |

Not a consumable e.g. oil, filter, etc. |

|

Is not consumable e.g. oil, filter, etc. |

Has a maintenance requirement and/or a defined preventative maintenance schedule |

|

Intangibles |

Usage history is required to be tracked (costing, work order history, utilisation, failures) |

|

Portable and Attractive items |

Critical equipment - unique or expensive hardware, tools, diagnostic equipment etc. |

|

Rotable piece of equipment (i.e. can be removed from service, rebuilt, and then held as a spare to be installed elsewhere) |

What is a Location?

While an asset in the EAM represents a singular physical item, a location is used to represent a position or place where a type of asset can be installed. The location captures the data required to know what could be installed in the position, in a similar fashion as a geometric network sets rules in a GIS environment (e.g. pipes connected to control valves). For facilities, this concept is encapsulated in a Piping and Instrumentation Diagram (P&ID) and increasingly in a 3D Building Information Model (BIM).

The location from an asset management focus is telling a maintainer what minimum requirements need to be met by any asset installed in that position. This separation is especially relevant where mechanical and electrical components are used, as it is possible to have a number of spares available that will only “fit” into certain locations and which locations will be identified by matching the specifications of the asset to the minimum requirements of the location. A location remains constant across the life of a network or facility.

Managing asset and location data

EAM applications can record simple point locations. GIS applications can record a variety of asset attributes. Designing effective solutions relies on understanding the strengths of each system and how they relate to your business and asset management objectives.

EAM systems are well suited to assets, such as mechanical and electrical components (motors, pumps, valves), that share a common set of attributes:

- they exist at a definable point at any one time

- they may move between locations as failures and change outs occur

- they may be made up of smaller items which can be itemised on a bill-of-materials (BOM)

- they are repaired/replaced in their entirety, rather than in segments

- condition and life expectancy can be regularly monitored and updated

In comparison, GIS solutions excel in situations that require linear or spatial representations or analysis of the interactions between components of an asset network. For example, how shutting down a valve for maintenance will impact water supply for customers connected to that valve.

Where there is a role for both systems within the asset information ecosystem, integration design needs to consider the ownership, control and exchange of data between them. Asset data should remain the responsibility of the EAM and inherit location data from the GIS to allow components to move between positions without the need to manually update attributes to reflect the new installed location.

Asset Lifecycle Phases and Data

There are generally three distinct phases of infrastructure asset management: Design and Construct, Operate and Maintain and Disposal. No single system best meets all requirements of these phases. Each phase will have one or more specialist software solutions that come together to deliver a best fit complete solution. The need to share information between systems is what leads companies to try and compress all asset information requirements into a single software solution. However, the risk with this approach is that it typically leads to compromises being made; compromises that would not be required where a integrated ecosystem approach is adopted upfront.

Design & Construct

The following table provides a high-level overview of the Design and Construct lifecycle phase, the data available at each stage and where it should be captured. Populating data too early into the GIS or EAM solution will result in a high volume of changes in one or more systems with little to no value for Asset Managers. However, populating data too late can result in a delay in performing required maintenance activities or performing incomplete maintenance regimes leading to real cost / impact to the business.

|

Stage |

What |

System |

Shared With |

Data |

|

Issued for Detailed Design |

Conceptual Locations |

^*# Modelling Solution |

||

|

Issued for Construction |

Confirmed Locations |

^*# Modelling Solution |

GIS |

Location Shells |

|

Issued for As Constructed |

Validated Locations |

^* Modelling Solution # GIS |

EAM |

Locations with specifications |

|

Construction Completions |

Validated Locations |

^* Modelling Solution # GIS, BIM (emerging) |

EAM |

Locations with confirmed specifications |

|

Installed Assets |

^ Modelling Solution *# EAM |

GIS |

Assets with basic details |

|

|

Commissioning |

Validated installed Assets |

*# EAM |

GIS |

Assets with Confirmed specifications |

^ Data Initiated from * Data Owned By # Data Maintained in

Operate & Maintain

For Asset Managers, the critical transition point of any new asset / location combination is the commissioning stage as this point (assuming no defects) is the transition from construction to operation. It also marks the first time that operational maintenance activities are initiated.

The following table outlines the most suitable System of Record for asset changes that occur during the Operate & Maintain phase and associated actions. System of Record (SoR) is an important concept in designing integration solutions that we'll explore in more detail in future posts, but for the purpose of mapping and understanding the flow of data through the asset information ecosystem, the System of Record for business data (or more likely, a specific field) is the original master copy of the information and will overwrite all other systems if updated.

|

Action |

System of Record |

Linked Systems |

Related Action |

Related Action Completed in |

|

Asset Move |

EAM |

GIS |

||

|

Asset Service Address |

GIS |

EAM |

Location Service Address |

GIS |

|

Asset Utilisation Reading |

SCADA |

EAM, GIS |

PM Work Order Generation |

EAM |

|

Create Asset |

EAM |

GIS, Finance |

Asset Creation |

GIS |

|

Update Location Data |

GIS, BIM (emerging) |

AMS |

||

|

Update Asset Data |

EAM |

GIS, Finance |

Disposal

Depending on Asset Class, asset commissioning and disposal will occur quite frequently and it's important to capture the old and new asset information at a location for both operational and financial reasons. For example, mechanical and electrical assets commonly complete a full lifecycle from installation to disposal. In particular, rotable spares may complete multiple service lifecycles when the asset is installed and operates until it is removed for refurbishment and reinstallation at a new location.

More rarely, locations may be disposed when a facility is upgraded or retired. In this scenario, all assets at the location need first to be removed or disposed.

The following table outlines the most suitable System of Record for the asset disposals phase and associated related actions:

|

Action |

System Of Record |

Linked Systems |

Related Action |

Related Action Completed in |

|

Asset Retirement |

EAM |

GIS (linear) |

||

|

Location Disposal |

GIS, BIM (emerging) |

Modelling Solution, EAM |

Removal of any linked assets before disposal |

EAM |

Conclusion

Reliably accessing accurate asset information when and where its needed to make decisions is the cornerstone of effective asset management. We've previously explored the value of location as the central point of entry to asset information from a variety of sources through GIS in an integrated asset information ecosystem. By digging deeper, we now see the key attributes to making it a success. Clearly defining the who (System of Record), what (Asset/Location), where (EAM vs GIS) and when (asset lifecycle phases) provides the framework to architect solutions that will help eliminate unnecessary, duplicate, and out-of-process data.