At a glance

- Discover why data chaos happens in Maximo and other EAM systems.

- Learn a practical, two-part approach to fixing root causes and symptoms.

- Explore how COSOL’s Maximo Data Portal simplifies validation, cleaning, and control.

- See real-world results from a rail operator’s journey from data mess to meaningful insight.

Article by Graham Drinkwater,

IBM Sales Leader at COSOL Americas

At the recent WMMUG 2025 event in Denver, I had the chance to speak with IBM Maximo users across the West Mountain region about something most of us know all too well: data chaos.

If you’ve worked in Maximo for long, you’ve probably dealt with it: duplicate records, inconsistent hierarchies, missing values, and unreliable information that slows everything down.

I know that this isn't just a Maximo issue - my colleagues who work in SAP and Ellipse tell me they face a similar challenge. So, although this presentation is skewed toward IBM Maximo users, what I share is really ERP or EAM agnostic.

First, a bit of context about us.

At COSOL, we believe reliability should go beyond just your physical assets - it should apply to your data, your systems, and your partners. Because when reliability matters, it matters everywhere. That’s likely why I was invited to speak at this event - reliable data is at the core of what we do.

So let me take you through the discussion, the realities I shared, but more importantly, the solutions.

How Maximo data chaos starts

The thing is, Maximo doesn’t start broken. But over time, things slip:

- Teams change

- Integrations add complexity

- Shortcuts become habits

- Standards get forgotten

Eventually, you’re no longer working with reliable data - and without it, even the best asset management and maintenance strategies start to fall apart.

When data isn’t reliable, performance suffers

This isn’t just a tech issue -it’s a reliability issue. Unreliable data affects:

- Planning and scheduling

- Procurement and inventory

- Safety and compliance

- Decision-making and reporting.

Bad data leads to bad outcomes. And in asset-centric industries, like mining, transportation, utilities, infrastructure, and government, the cost of unreliability is high - delays, downtime, and lost trust. All very expensive.

Why the old fixes don’t stick, but what will?

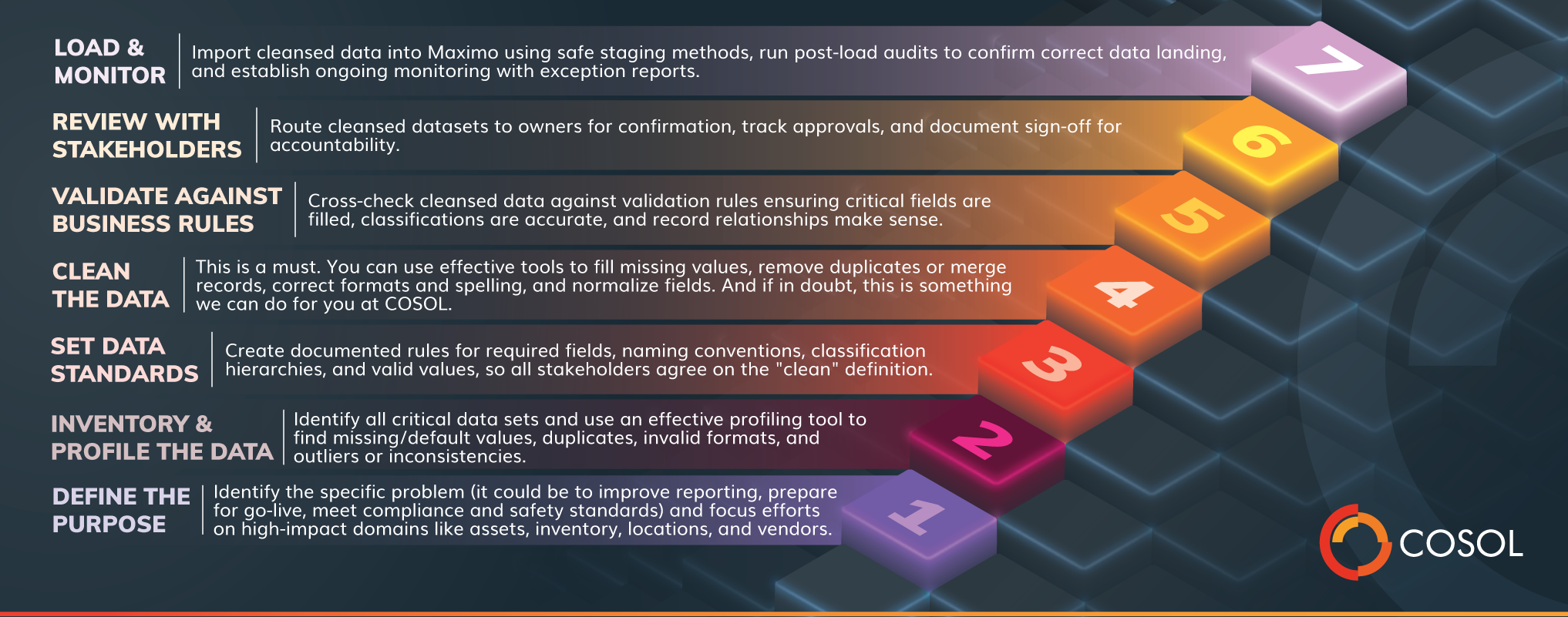

I’m a firm believer that traditional fixes - like periodic clean-ups or one-off audits - don’t solve the underlying problems. Why? Because this approach is like treating the symptoms instead of the root cause. The simple truth is that without governance, clear standards, and shared accountability, the chaos comes back.

Needless to say, it was a crowd pleaser. There is something else that can help that I shared with the attendees...

- Define comprehensive data standards for all use cases to establish clear guidelines

- Assign dedicated data stewards to take ownership of data quality

- Ensure manual data entry processes follow established standards through training and validation

- Constrain data loading procedures to enforce standards at all entry points

- Implement ongoing monitoring and auditing to maintain data integrity over time.

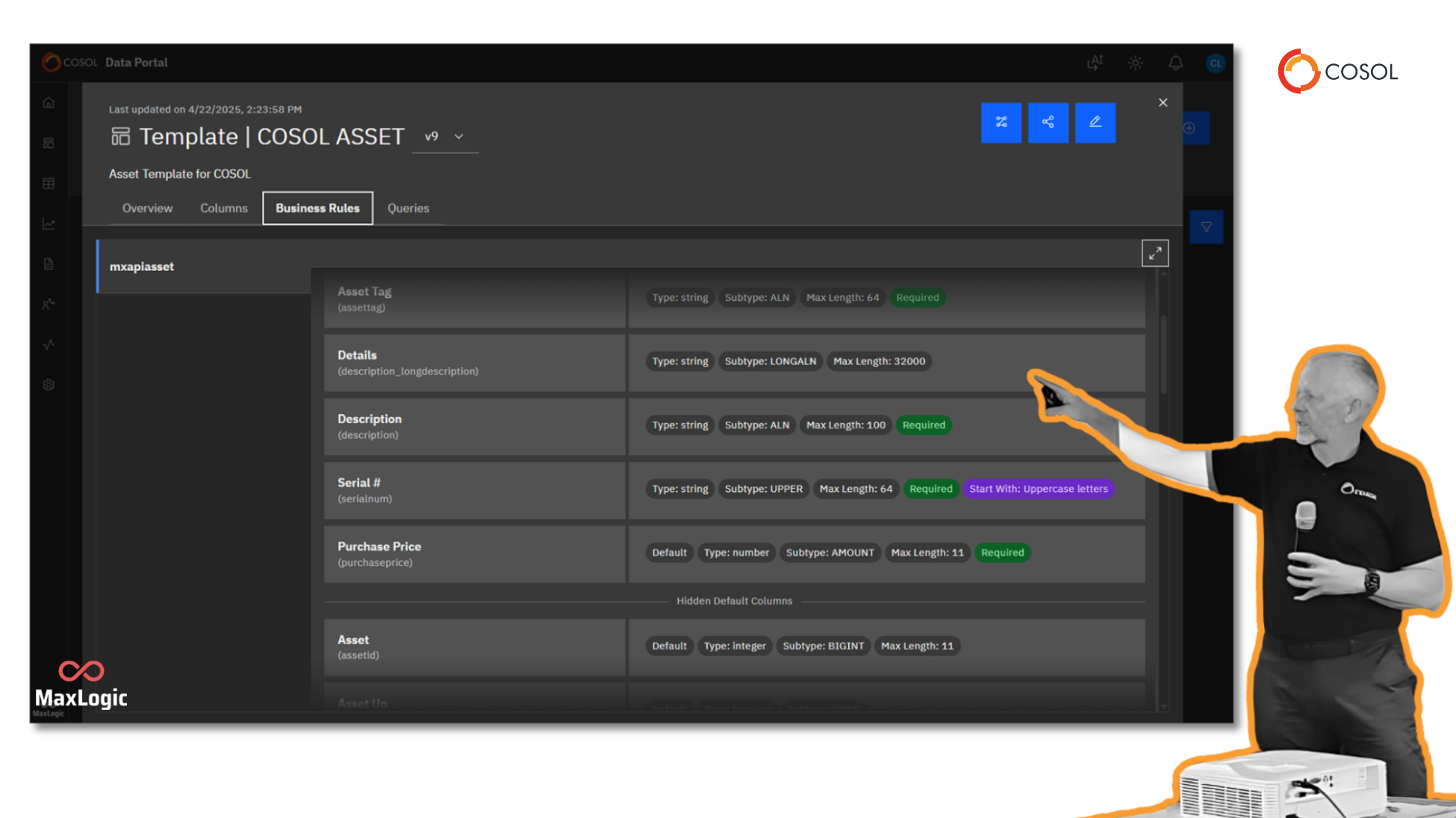

Want a simpler solution? It’s called the COSOL Maximo Data Portal

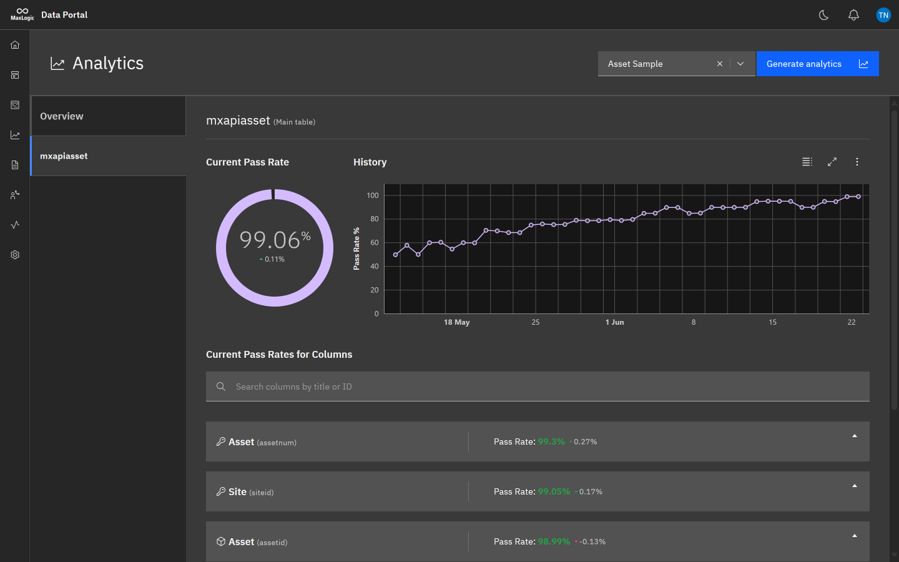

To help IBM Maximo teams take back control, I shared something we’re really proud of: the COSOL Maximo Data Portal, powered by MaxLogic.

It’s a powerful, intuitive platform that simplifies data validation, cleaning, and loading for Maximo 7.6 and MAS. Whether you’re cleaning legacy data or managing ongoing changes, the portal puts you in control with confidence.

What does it do, and what value will it bring asset management folk who use IBM Maximo? Here are seven that come to mind:

- It’s built for Maximo – Seamless integration with Maximo 7.6 and MAS

- It’s easy on the eyes – It has a modern Interface, i.e. clean dashboard powered by IBM Carbon UI

- You’ll be able to define and enforce standards – Set your own data quality rules

- Existing rules in Maximo (standard or your own) are automatically enforce,d while additional rules can be defined in the portal

- Fix issues in place – Edit and correct data directly in the portal

- Automate workflows – Streamline validations and approvals

- Deploy anywhere – SaaS, private cloud, or on-premises options available. You choose what works for your operations.

Why reliable data changes everything

We’d all agree, when your data is reliable, everything else runs better:

- You reduce unplanned downtime

- Maintenance becomes predictive

- Compliance and audit readiness improve

- AI and analytics finally work as promised

- You protect your investment in Maximo and MAS.

These are all objectives that asset management leaders around the world can relate to. So, if your Maximo data isn’t supporting your goals, let’s talk. Whether you’re prepping for MAS or simply want to get more out of what you’ve already built, we can help you get there - cleanly, confidently, and yes, reliably.

The proof of the pudding is in the eating

Over the decades, I’ve seen firsthand how small data issues can create big reliability problems, and just how powerful the turnaround can be when you fix them properly. One case that really stuck with me involved a major rail operator in the UK. They were drowning in inspection data but couldn’t get a single useful insight out of it.

It’s a very simple, yet good example of how structured, reliable data can make a real-world impact. Let me walk you through what we found, how we addressed the data chaos and how it impacted the rail organisation.

Case Study: From Data Chaos to Clarity: How a Rail Operator's Inspection Data Black Hole Was Fixed

THE PROBLEM

A major rail operator contacted us because they were spending thousands of dollars on regular infrastructure inspections but couldn't extract any meaningful insights from the data. Their maintenance director was frustrated - they had years of inspection records in Maximo, but when they tried to analyze trends or identify recurring issues, the reports were virtually useless.

THE APPROACH

We spent a couple of days in the field with their inspection teams as they carried out their routine safety inspections along the rail corridor. What we discovered was eye-opening: inspection results were being entered manually as free-form text in a single description field, with no standardized format or terminology.

The most telling example was their galvanized light poles. These critical safety assets were being described in seven different ways (!) depending on who performed the inspection: "galv light pole," "galvanized lighting post," "GLP unit," "light pole - galvanized," "galv. pole (lighting)," "galvanised streetlight," and "lighting pole/galvanized."

When the operations team tried to run reports on light pole condition trends, the system couldn't correlate records for the same asset type because each variation was treated as a completely different category.

Years of valuable inspection data were essentially locked away, unusable for predictive maintenance or capital planning.

We knew what we had to do then and there: Implement structured inspection templates with standardized terminology and dropdown menus and retire the error-filled manual entry.

THE IMPACT

They were finally able to see patterns in their data. In fact, within six months, they identified that galvanized light poles in coastal sections had a 40% higher corrosion rate, leading to a targeted replacement program that prevented several potential safety incidents.

The maintenance director summed it up perfectly: "We went from drowning in data to actually swimming with insights."

And that was, well, music to my ears.

About Graham Drinkwater

Graham has over 22 years of experience in Maximo and MRO IO solutions. As a proven and trusted customer partner, Graham has guided organizations through all aspects of Maximo lifecycles, from initial implementation to optimization and upgrade strategies. His extensive expertise in enterprise asset management systems and deep understanding of maintenance, repair, and operations processes make him a recognized authority in the Maximo community.

Book in a COSOL Maximo Data Portal demo or connect with me on LinkedIn.

About COSOL

COSOL is built on one belief: in asset-centric industries, reliability is everything.

We’re a trusted, data-led asset management partner for organisations around the world who can’t afford to fail.

With over 25 years of experience, we combine deep industry expertise, dependable delivery, and powerful digital capabilities - including AI, data, and proprietary software - to help our clients reduce downtime, improve performance, and optimise the full asset lifecycle with confidence.

From mining and energy to infrastructure, transport and government to defence, our clients trust us to work as part of their team - responsive, easy to work with, and focused on outcomes that matter.