At a glance

- Why Change? Triggered by compliance pressures and real-world incidents, CITIC Pacific Mining recognised paper-based systems were no longer enough.

- Avoid the Pitfalls: Common barriers like data silos, rushed rollouts, and poor user engagement can sink digital projects if not addressed early.

- Phased, Not Forced: A hybrid rollout, digitising at a steady pace while keeping familiar systems, helped build trust and minimise disruption.

- Real Results: Digitisation unlocked safer, faster, and more efficient maintenance with connected data, flexible processes, and stronger frontline engagement.

Owning and operating heavy machinery means keeping safety, reliability, and performance front and centre. For asset-centric operations, digital inspections are becoming a powerful way to stay ahead on all fronts.

At COSOL, we see the same opportunity on a broad scale. Digital work management isn’t just about jumping on the latest tech bandwagon - it’s about making what already works even better. It’s about smarter, smoother, more connected operations without throwing tried-and-true processes overboard. In our recent webinar, “Digitising Work Management: Planning for Success,” we dug into how organisations can embrace transformation and unlock big wins without hitting any icebergs and sinking the ship.

We were joined by COSOL client Sunil Rodrigues, Manager of Asset Management at CITIC Pacific Mining and the session was led by Sam Crewe, OnPlan Product Manager at COSOL. The session surfaced a wealth of practical takeaways from a digital journey that’s modernising maintenance across one of Australia’s largest mining operations. And today we are sharing some of the highlights with you.

Why Digitise Asset Maintenance? The Tipping Point

Often, there is a tipping point that gets us on a new path, for often businesses will say, “Why change if things are working well?”. The journey at CITIC Pacific Mining (CPM) began not with a desire for shiny new tech, but out of necessity. Sunil shared, “We had a paper-based process where data was captured but not recorded effectively. There was no feedback loop from the inspections we were doing”.

Two events further accelerated their move: stricter regulatory requirements under the 2022 WA Workplace Health & Safety Act, and an insurance claim after a wheel loader fire. “We had to rummage through archive boxes to find paperwork that was years old… That was our moment - we needed to move forward.”

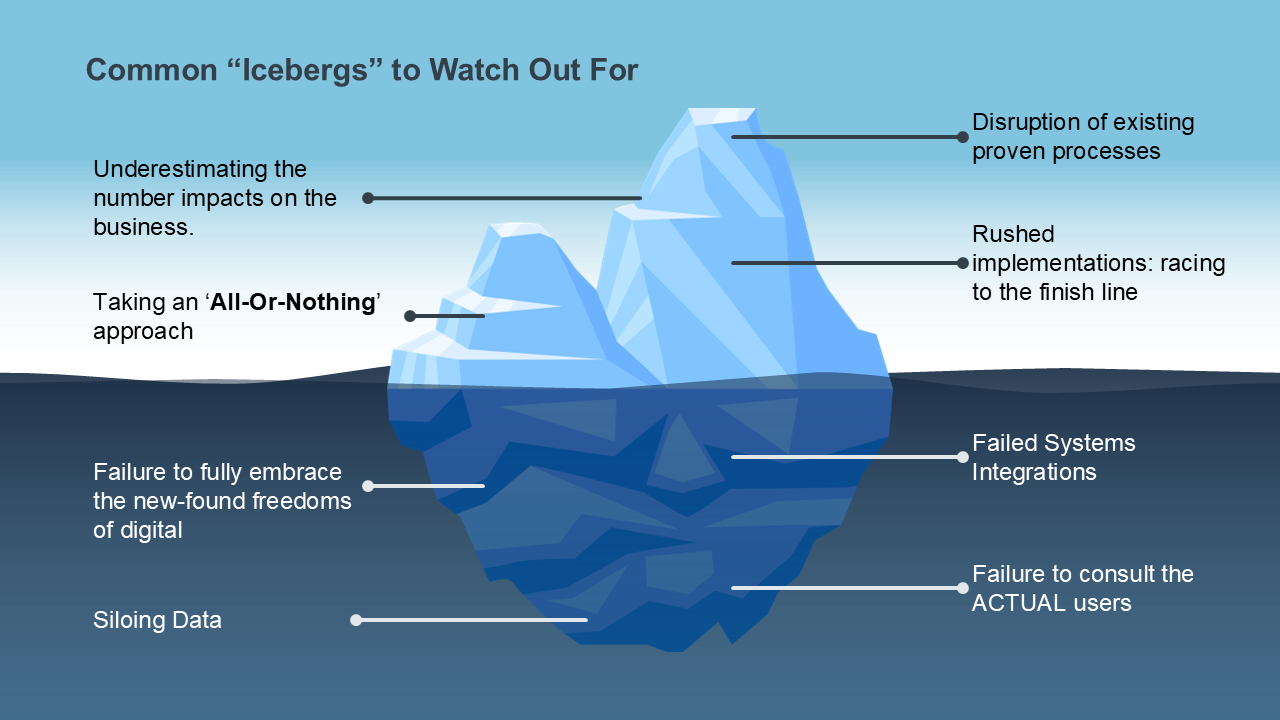

Spotting - And Avoiding - The Icebergs

But change can open a can of worms when not done right. As the initial slide shared:

Success doesn't just happen

IT'S ENGINEERED

Building Trust Through Phased Change

For Sunil, one of the most important lessons was to preserve confidence. “Management and techs alike were losing faith in the systems. We knew this project had to work - we couldn’t afford a false start.”

The team took a smart, steady approach - starting by digitising documents but keeping their trusty SAP links right where they were. No big bangs. No chaos. Just a smooth, phased rollout that lets everyone ease into the change without missing a beat.

Embracing The Freedom Of Digital Asset Maintenance

Switching to OnPlan wasn’t just about copying old processes into a shiny new system - it was about unlocking totally new possibilities. It’s a real-deal digital work management setup that’s fast, intuitive, and, yes, even likable. Now, technicians can snap photos, log data, and sign off jobs in real-time - all without the paperwork pile-up.

“They can confirm tasks and time on the job without the manual paperwork that used to slow us down,” said Sunil.

One of the unexpected wins? Safety. “We have the capability to digitise our ‘Take 5’ pre-starts and linked hazards and PPE (Personal Protective Equipment) directly to tasks,” he shared. “Instead of losing those conversations in archive boxes, now can be capturing safety data that will provide insights from which we can actually learn from.”

COSOL OnPlan’s flexibility turned out to be a huge win.

Make Data Work For You

Sam highlighted a major shift: “You’ve always been capturing good data, but connecting it is what completes the feedback loop.” Sunil agreed. “Otherwise, it’s just a waste of time. Capturing data has to help you optimise, make changes, and manage assets better.”

Instead of printouts and binders, technicians now have digital instructions and links to the latest procedures.

The Hybrid Approach: Digital Without Disruption

Change management is often where digital projects stall. Sunil’s advice? “We didn’t force the entire site to go digital. We let departments pilot the system when they were ready, and kept paper as a fallback. That hybrid model gave us time to win hearts and minds”.

Sam added: “With OnPlan, digital and paper-based processes can exist in one system. You’re not duplicating work - you’re evolving it.”

Sunil's Advice to Others: Know Your Why

For those beginning the digital transformation journey, Sunil offers one clear piece of advice: