At a glance

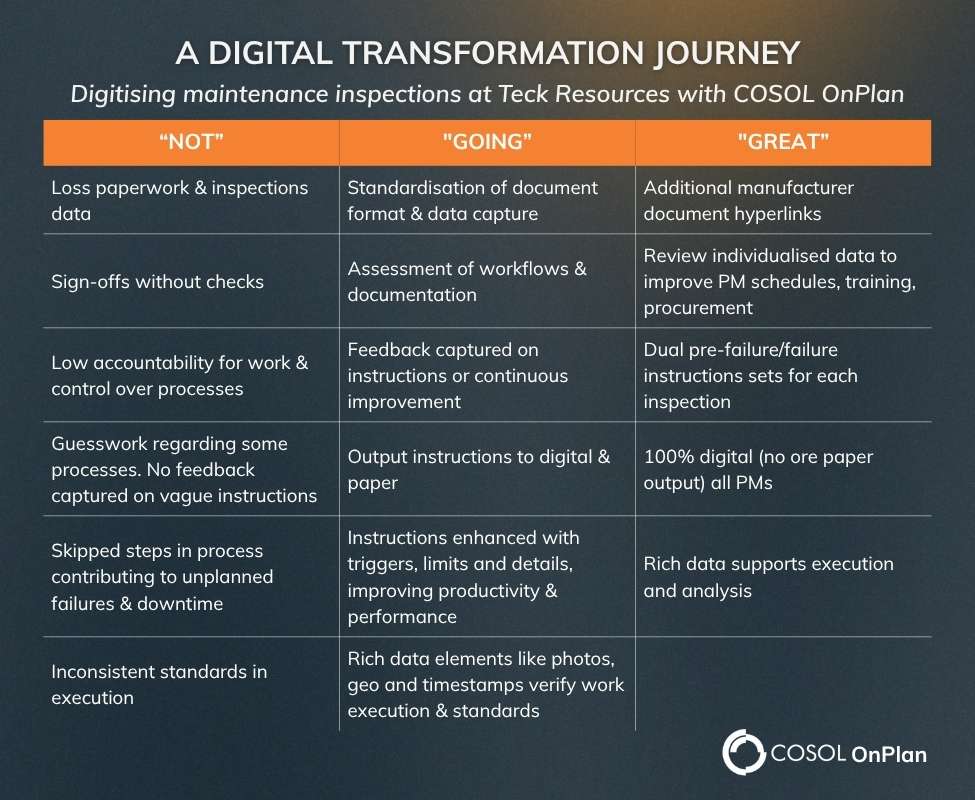

- Transitioned from paper to fully digital inspections with OnPlan

- Improved accountability and reduced manual errors in maintenance

- Enhanced analytics for scheduling, training, and equipment investment

- Significant reduction in downtime and unnecessary PM work

Getting started: Tips

Start strategically

"Assess what you want to record, monitor or access at the asset and work back to the document. You need to pay consideration to how specific trades or individuals are going to work through the function and the associated instruction,” he said.

He recommends that instructions are reviewed and streamlined where necessary before they’re transformed into digital.

Select the most common equipment first

Don't just import documents

Moore recommends digitising one model of equipment at a time, and selecting the most important function on that equipment first. This boosts scale and return on investment by laying a foundational digital document for similar models.

“As we came to realise that we weren’t physically restricted to the one-line instruction anymore in the digital format, we designed a new, standard document structure for all digital inspections built in OnPlan."

Standardise document format

“We've re-structured all digital documents so we could enrich instructions with detail, but still keep it quick and easy to get to work,” said Moore.

“Now we have a short description at the top of the instruction, with all pass/fails in the next section. We have instructions on what to do if you find a fail, and further detail on each job step available by scrolling further down the screen, in case it’s needed by the user, depending on their experience,” he said.

These templates improve the scale of the digitisation and meanwhile, improve ease of use and adoption for execution teams.

Keep paper copies, too

Teck continues to output instructions to paper and digital via the OnPlan mobile app.

Moore explains: “We have 350 maintenance personnel per hour on site, 20% of that workforce are on PMs. So, there’s still a chance that shifts will change, introducing someone that’s never seen OnPlan to complete a task.”

Get Going: Tips

User training & support

Teck coordinated classroom training, but focused on check-ins with users while in-field when introducing OnPlan to its Technicians.

Surprisingly, when presented with digital instructions via the OnPlan app, several users initially mistook the new digital format for brand-new process, rather than one they were already familiar with.

Get going, then go for great

This includes a commitment to reviewing inspections data captured via OnPlan to identify redundant checks. “The plan is to identify where we’re capturing the same

data every time, to assess the need for that check and remove it from particular routines,” said Moore.

Teck has found the rich historical record and visuals on crack growth at the asset via OnPlan has reduced the instance of unnecessary PMOs.

“Our welding team has been able to monitor cracks more confidently at the asset so that work can be delayed until the next PMOs cycle, or for a shutdown,” said Moore.

Get Great: Tips

Enhancing digital instructions

Teck has already started to enhance digital inspections and instructions with hyperlinks to manufacturer’s documents.

This has significantly reduced load upon Supervisors, who have previously had to be ready to respond with what to do upon identifying a failure on a variety of equipment.

Teck also plans build in dual criteria for what is a ‘pre-failure/failure’ mode, so instructions guide the user what to do when an inspection finds what can wait for the next PM cycle, or if it needs to be raised as break-in work.

Enhanced analytics

Improved control

Even before individualised logins were rolled out to the OnPlan users, Teck Trades immediately became more accountable for their work in the digital format. In part, this

is because Teck is asking for confirmation, or a ‘yes’/’no’, ‘accept/reject’, ‘pass/ fail’ for components of a process

The additional data, digitally captured at a user level will help Teck to optimise processes even further.

“We’ll aggregate more user-level information like time on jobs, pass/fail ratios, the rates of identifying cracks to inform scheduling, procurement and training requirements,” he said.

About COSOL

COSOL is built on one belief: in asset-centric industries, reliability is everything. We’re a trusted, data-led asset management partner for organisations around the world who can’t afford to fail. And known for our deep expertise, dependable delivery, and ability to keep critical assets performing at their best.

The company recently celebrated 25 years in business, are Australian-owned and operated, and recognised as reliable partners by their clients across the globe.

when reliability matters, paper won't cut it

Transform Your Asset Maintenance with Smart Digitisation